Who we are at Auditing Consulting Services LLC

Our Values

At Auditing Consulting Services LLC, we believe in honesty, integrity, and hard work. We treat every customer with respect and strive to exceed their expectations. We are committed to safety and always follow industry best practices to ensure the well-being of our team and our clients.

Mission Statement

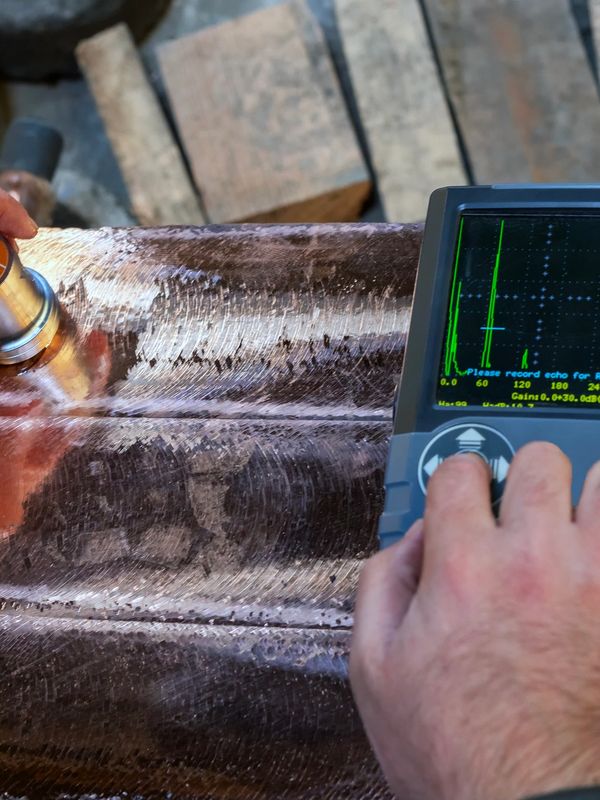

- Our Inspectors are experienced in welding inspection for existing or new installations for industrial equipment, oil & gas, power equipment, pipes, renewable energy, transportation, aviation, metallurgy, steel structure, wind turbines, and many more. We bring the needed flexibility and geographic coverage to meet the lofty standards of large companies, and the needs of small and medium-sized companies. Auditing Consulting Services include:

- Document Review

- Welding and fit up Inspections

- Visual Inspections

- NDE

- Training

- Cad Drawings

- P&ID Updates

- Our inspection reports are delivered within 24 hours and record all inspection points relevant to quality, including all identified weld imperfections and digital pictures.

NDT Training AND 40 HOUR RADIATION SAFETY TRAINING

ACS is a consulting and training company with extensive NDE training programs, testing services. ACS has developed a prominent standing with education, business, manufacturing and insurance industries, and the legal community for effectively discovering facts in nondestructive examination testing, consulting engineering, metallurgy and materials testing, mechanical testing, chemical analysis, and calibration services.

Our Training Courses

ACS’ NDE Training classes are created to appeal to professional men and women who perceive that their NDE technical education, skill, achievement and certifications can contribute to the comprehensive success of the NDT industry.

We offer an all-inclusive and beneficial array of course programs that are competitively priced and accommodating. Our programs promote interactive learning environments which exceed industry standards and conclusively develop students to become leaders in one or all of the nondestructive examination testing methods. NDE training is provided year-round in all complementary industries with multiple courses or programs occurring weekly.

Onsite Training

ACS’ NDE training courses are conveniently available for learning and demonstration at your facility. A course at a client’s facility is a cost-effective way for a hands-on approach that is able to accommodate to their specific and full-scale needs.

Welding Inspection Training

This course will teach you the duties and responsibilities of a CWI and API welding inspector including fusion welding processes, typical weld defects, types of steel (including carbon-manganese, low alloy and stainless steels), the hardening of steels, weldability, heat treatment, and parent metal defects.

The program will also include visual inspection, the testing of parent metals and welds, and destructive and non-destructive test techniques.

You will also learn welder and procedure approval, codes such as API, ASME, NBIC, AWS, Standards, and an outline of safe working practices.

There will also be the opportunity to practice examination questions while undergoing continuous and end-of-course assessment, you will be able to complete the relevant examination on day 4 of the course.

Code and Jurisdiction Inspections and Training

Code and Jurisdiction Inspections

- API Inspections

- AWS Inspections

- ASNT Audits

- Welding Audits

- Pipeline Inspections

- NDE Audits

- Quality Control

- RSO Audits

API 570

API 570

API 570

This 40 hr. course provides a comprehensive overview of the applicable portions of the following codes: API Standard 570, Inspection, Repair, Alteration, and Rerating of In-Service Piping Systems; API RP 571, Damage mechanisms Affecting Fixed equipment in the Refining Industry; API Recommended Practice 574, Inspection Practices for Piping System Components; API RP 577, Welding Inspection and Metallurgy; API Recommended Practice 578, Material Verification Program for New and Existing Alloy Piping Systems; ASME American Society of Mechanical Engineers (ASME) Boiler & Pressure Vessel Code: Section V, Nondestructive Examination; Section IX, Welding and brazing Qualifications . $1200.00

API 510

API 570

API 570

This 40 hr. course is recommended for those candidates that prefer a complete course that is “walk in ready” for the API exam: It provides a comprehensive overview of the applicable portions of the following codes: API 510, Pressure Vessel Inspection Code; API RP 571, Damage Mechanisms Affecting Equipment in Refining Industry; API RP 572, Inspection of Pressure Vessels (except Appendix B); API RP 576, Inspection of Pressure-Relieving Devices; API RP 577, Welding Inspection and Metallurgy; ASME Section V, Nondestructive Examination; ASME Section VIII, Division 1, Rules for Constructing Pressure Vessels; and ASME Section IX, Welding and Brazing Qualifications. Hours. $1200.00

API 653

API 570

API 653

This 40 hr. course provides a comprehensive overview of the applicable portions of the following codes: API Recommended Practice 571, Damage Mechanisms Affecting Equipment in Refining Industry; API Recommended Practice 575, Inspection of Atmospheric and Low-Pressure Storage Tanks; API Recommended Practice 577, Welding Inspection and Metallurgy; API Standard 650, Welded Steel Tanks for Oil Storage; API Recommended Practice 651, Cathodic Protection of Aboveground Petroleum Storage Tanks; API Recommended Practice 652, Lining of Aboveground Petroleum Storage Tank Bottoms; API Standard 653, Tank Inspection, Repair, Alteration, and Reconstruction; ASME American Society of Mechanical Engineers (ASME) Boiler & Pressure Vessel Code: Section V, Nondestructive Examination; Section IX, Welding and Brazing Qualifications. $1200.00

CWI

40 Hour Radiation safety

ASNT LEVEL II AND III

The American Welding Society “Certified Welding Inspector” preparatory course is designed to offer the applicant the knowledge and ability to pass the CWI/CWE test. The course covers the navigation of American Petroleum Institute Standard 1104 as well as practical solutions for complying with the code. The course also covers the theoretical science behind metallurgy, inspection practices, and non-destructive examination. The participants will receive instruction in the following necessary skill blocks: The CWI course will be 5 days (approximately 50 hrs.) starting on Fridays, ending on the following Friday followed by the Part B Exam on Saturday. ACS has elected to offer the 5-day prep course to allow the students to be better prepared for the exam. This gives each student more course prep time and allows the instructors more individual time with students. This will only increase students' knowledge, have the student more prepared for the exam, and help the students' investment in passing the exam. The American Welding Society (AWS) and proctors will then administer the Part B Exam ONLY on Saturday following the prep course. The other 2 sections of the Exam, Part A and Part C, will ONLY be administered at a Prometric Computer Based Testing Facility. All 3 exams are timed. Please refer to the AWS Website for more details on the Exam. $1300.00 5 Days

ASNT LEVEL II AND III

40 Hour Radiation safety

ASNT LEVEL II AND III

There are three Nondestructive Testing or NDT levels of certification known as NDT Level I, Level II, and Level III. Each NDT level has its own requirements. You’ll also have to pass written and practical examinations for every NDT certification level.

The market for nondestructive testing is worth over $14.8 billion. It’s an effective way to prevent mechanical failure and ensure component life cycle and safety. An NDT technician performs specialized tests and must demonstrate that they have the necessary skills and experience at the required NDT levels. The best way to do this is to receive NDT certification.

Level I and II

RT LEVEL I and II $1500.00 4 DAYS

VT LEVEL I and II $800.00 2 DAYS

MT LEVEL I and II $800.00 3 DAYS

PT LEVEL I and II $800.00 3 DAYS

UT LEVEL I and II $1800.00 5 DAYS

Level III

BASIC LEVEL III $1500 4 DAYS

RT LEVEL III $1500.00 4 DAYS

VT LEVEL III $1100.00 2 DAYS

MT LEVEL III 1100.00 3 DAYS

PT LEVEL III 1100.00 3 DAYS

UT LEVEL III $1100.00 5 DAYS

40 Hour Radiation safety

40 Hour Radiation safety

40 Hour Radiation safety

This 40-hour course on Industrial Radiography is designed to meet the training requirements for formal certification in Radiation Safety for both X-ray and gamma Radiographers.

- Course materials cover the requirements of the Department of Transportation and the Nuclear Regulatory Commission.

- Our instructors outline the “Suggested State Regulation for Controlling Radiation (SSRCR)” as well as the topics listed in Appendix A to ASNT CP-105-2011 (excluding neutron radiography).

- This 40-hour radiation safety course exceeds the recommendations and training outline set forth by the NRC training manual available as NUREG/BR-0024 Working Safely in Gamma Radiography and its subsequent ASNT revisions.

- The course addresses required training topics for radiographic personnel specified in federal (10 CFR 34.43) and equivalent state radiation control regulations and the topics listed in Appendix A to ASNT CP-105-2011 (excluding neutron radiography). $700.00 4 days

Contact Us

We love our customers, so feel free to visit during normal business hours.

Auditing Consulting Services LLC

Hours

Open today | 05:00 am – 06:00 pm |

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.